August 02, 2023

MP Filtri: Patch Imaging Kit and filter recalibration service

#Italy@bauma #hydraulic #filtersMP Filtri offers a new Patch Imaging Kit dedicated to end customers and a filter recalibration service

MP Filtri for 2023 offers two significant new entries presented in preview at the last bauma: the new Patch Imaging Kit dedicated to customers and an interesting service for the recalibration of the MP filters themselves. These are two complete solutions designed for an increase in the performance of the filtering systems for greater operational continuity of the hydraulic systems.

Fluids’ contamination monitoring

MP Filtri's Patch Imaging Kit was designed as a supplement to MP Filtri's inline portable particle counters offering highly accurate, real-time inspection of contaminants in fluids. The new Patch Imaging Kit includes a digital microscope that gives operators the ability to evaluate these particles under a microscope and identify potential sources of contamination.

The kit allows performing rapid and accurate tests on fluid samples and, by capturing contaminants on a membrane, it allows to carry out detailed analyzes through the digital microscope included in the kit, measuring, recording and offering the possibility of observing and evaluating individual particles.

By being able to visually evaluate their appearance and composition, it thus becomes possible to isolate the cause of wear within a system. For example, the presence of rubber particles suggests the decomposition of the hose, while the high content of metallic elements reveals the wear of pumps or mechanical components.

By identifying the specific causes of decomposition, maintenance personnel can thus replace worn components, protecting complex systems, extending the life cycle and reducing maintenance costs and downtime.

Patch Imaging Kit: how it is

The new Patch Imaging Kit consists primarily of a high-performance digital microscope, with magnification up to 400x which is combined with highly sophisticated software (which

The new Patch Imaging Kit consists primarily of a high-performance digital microscope, with magnification up to 400x which is combined with highly sophisticated software (which runs

on the Windows operating system) that allows the measurement and analysis of single particles.

The Patch Imaging Kit is a comprehensive test that facilitates rapid and accurate sampling, easy to use and without the need for specific training.

Recalibration MP Filters HQ

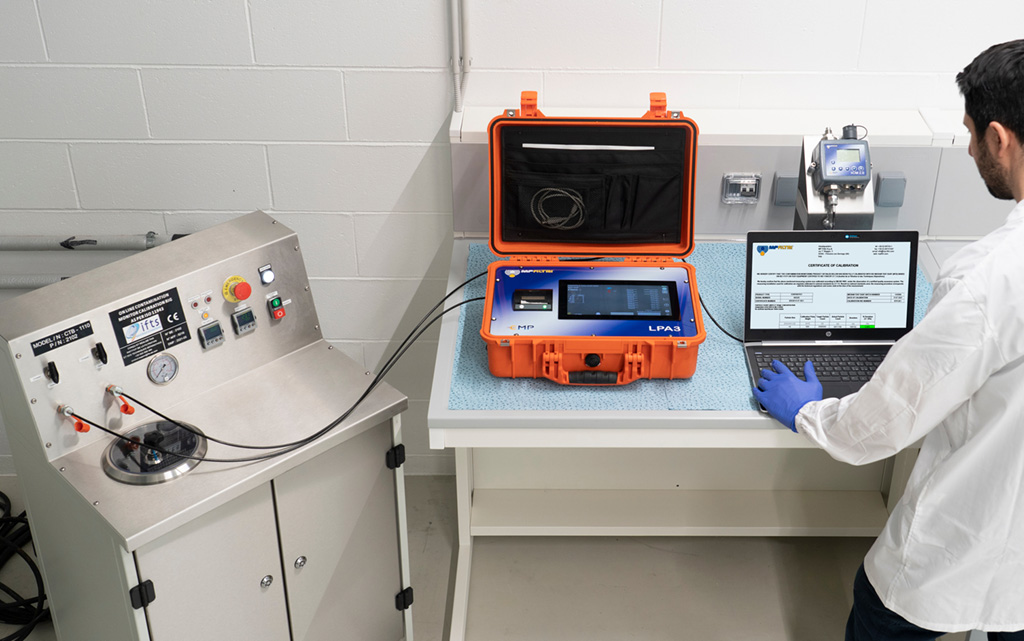

Recently MP Filtri has also launched a new machine: it is the new test bench dedicated to the recalibration of contamination monitoring devices. The recalibration of the meters is carried out on the basis of ISO 11171 and the test bench is certified according to ISO 11943.

But why is the recalibration of a particle counter necessary? The MP filter counters work with light beam extinction technology. The particles of solid contaminant present in the oil are counted and classified by size based on the electrical signal detected by the light photo-receptor which recognizes them as shadows.

Recalibration verifies and realigns photo-receptor operation. The test bench has the function of maintaining the test liquid (an oil with verified characteristics) in a constant condition of calibrated contamination provided that the size and quantity of the particles of this suspension are known in advance.

How does recalibration work

The MP Filtri recalibration software automatically adjusts the electronic counting system, realigning it to the target value. The combined test bench system together with the dedicated software also performs diagnostics of all the operating characteristics of the meter and, where provided, indicates which parts or components need to be replaced.

The MP Filtri recalibration software automatically adjusts the electronic counting system, realigning it to the target value. The combined test bench system together with the dedicated software also performs diagnostics of all the operating characteristics of the meter and, where provided, indicates which parts or components need to be replaced.

Always perfect monitoring

This system allows the customer to return the device intact, recalibrated and complete with all available updates, but above all quickly, considering that the recalibration service is performed completely within a week.

The customer can personally book the service online, through the dedicated section on the MP filter website.

Once all the checks have been completed, the customer is issued a calibration certificate which is valid for one year with the purpose of certifying that the product works correctly and that the readings performed are confirmed.